"We are gradually trying to automate individual warehouse operations. Automation within internal logistics brings an increase in efficiency, and it also solves the problem of the shortage of labour on the labour market. For us, the autonomous Agilox trolley from 4IGV also has the advantage that it only needs to read a map of the warehouse to operate, so it doesn't need any markers or tapes on the floor to move around," popisuje Ondřej Weiss, Operations Manager společnosti DHL, který má v distribučním centru Syrovice na starost zajištění skladování pro společnost TE Connectivity.

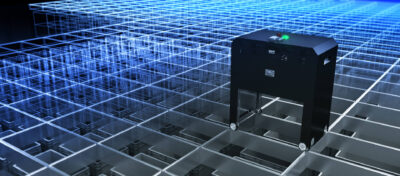

The Agilox intelligent AGV ensures efficient storage

The Agilox trolley uses a code reader. It knows where to take the pallet from the receiving area. "The advantage of the autonomous truck is that it is able to scan predefined locations and know whether or not there is a pallet to be picked up at a given position and if there is a vacant space or occupied area at the location where the pallet is to be taken. If the space is occupied, Agilox will take the pallet to what is known as an errored zone." says Ondřej Weiss.

He adds that the big advantage of 4IGV's Agilox is that it does not need to implement any system, it is an autonomous machine that has a system inside it. "With other autonomous machines, if you're getting more than one, you usually need to have some sort of control system that coordinates the machines with each other. That's not necessary with 4IGV's Agiloxes because their own system means that the machines communicate with each other. This can therefore save the company the cost of the system. The task is carried out by whichever truck is closest to the handling point, so pallet transports are efficient. Agilox is really great at this. Its operation is intuitive, user-friendly," says Ondřej Weiss.

He added that Agilox's controls are graphically clear and include a graphical representation of the layout in which it moves. On a computer, mobile or tablet, warehouse management can clearly see where Agilox is, add or remove positions, disable something, etc.

Automated pallet transport, intermediate recharging

"The Agilox truck is running on automatic. If it's not busy, it will recharge itself. We set it up so that every fifteen minutes it goes around the pickup zone to pick up pallets for transport. When we need to change something, we simply make the adjustment ourselves via the user interface," says Ondřej Weiss. He also mentions that if the trolley gets blocked on the route for some reason, it will immediately send an e-mail to the defined addresses with an up-to-date notification containing precise information.

DHL in Syrovice plans to automate order picking for loading in the future.

Help for repetitive transports in warehouses

The Agilox trucks from 4IGV pay off wherever repetitive transports are carried out as part of warehouse handling. "Automation in the form of our Agilox AGVs streamlines transport and warehousing processes, improves profitability and competitiveness, increases safety and helps overcome labour shortages," says Marek Matovcik, Managing Director of 4IGV. "The first trolley is proving itself in operation. If volumes increase, it is possible that we will purchase another Agilox autonomous truck," adds Ondřej Weiss.